We have created a awesome theme

Far far away,behind the word mountains, far from the countries

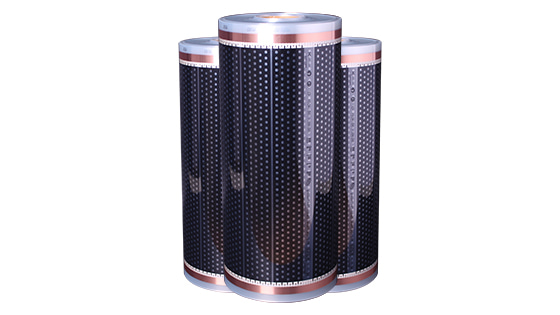

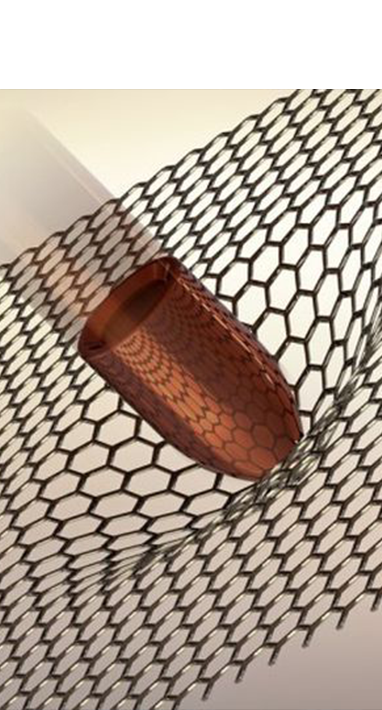

PTC graphene linear film heating

Item discription

카본 반도체가

발열하면서 원적외선 및 음이온을 방출하는 원적외선 복사열 난방방식으로에너지효율이 뛰어난 초절전형난방시스템입니다.

발열하면서 원적외선 및 음이온을 방출하는 원적외선 복사열 난방방식으로에너지효율이 뛰어난 초절전형난방시스템입니다.

또한, 청정에너지인 전기만을사용하여

실내공기를 정화시켜쾌적한 난방을 제공하며프리미엄 가치창출, 가볍고 얇은 필름으로 힛팅을 하므로, 난방 효울성이 높다

실내공기를 정화시켜쾌적한 난방을 제공하며프리미엄 가치창출, 가볍고 얇은 필름으로 힛팅을 하므로, 난방 효울성이 높다

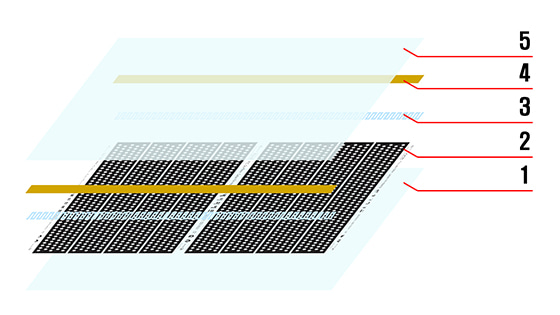

1 - PET film

2 - PTC graphene carbon paste

3 - Silver Busbar

4 - Copper foil busbar

5 - Laminex Film

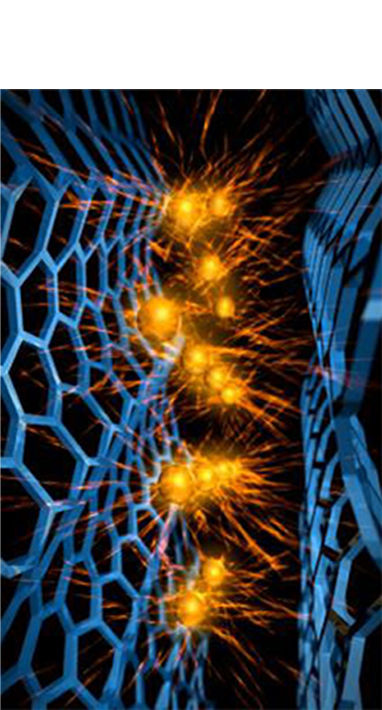

Advantages of PTC graphene film

High specific surface area

The specific surface area, which refers to the surface area per particle unit, is much wider than anything else in graphene. 3.2g of graphene powder can cover an area of a soccer field

High intensity

than diamonds. Graphene is a strong material. When combined with titanium used for aircraft and automobiles, the strength becomes stronger and the weight becomes lighter. Graphene is 200 times stronger than steel.

Flexibility

If it easily cracks or breaks on impact, would it be a great new material? Graphene is a new material that is in the spotlight because its properties do not change even when folded or bent

Transparency

The smartphone screens we use are made of ITO, an idium mineral, which is expensive and breaks easily on impact. Graphene can be used in the display area as an alternative to this ITO.

Electrical conductivity

Graphene has the ability to transmit electricity 100 times faster than copper, the metal that transmits electricity the fastest. Therefore, batteries using graphene can be used for a long time as well as ultra-fast charging. It becomes possible

Thermal Conductivity

How fast and with little energy can it heat up? Graphene has a high thermal conductivity of 5000K, more than twice that of diamond and more than 12 times that of copper.

Advantages of graphene film heating

◈ Fast thermal conductivity

The product with the best heat conduction on the planet

it's a diamond Twice as much as these diamonds

The product with fast thermal conductivity is graphene.

3 types of film heating in each room under the same conditions

In case of construction, PTC graphene film heating is

The installed room will reach the desired temperature the fastest

You can see it going up.

◈ leakage current compensation

One of the disadvantages of film heating is the leakage current

This leakage current can be compensated for

The product in existence is PTC graphene film heating.

PTC graphene film heating has high adhesion

Complete blocking due to the adhesion of PET

It is difficult, but the leakage current is much lower than that of conventional film heating

Removes it.

◈ Energy saving

How much film heating is operated by electricity

Saving energy is a very sensitive area.

Once the PTC function is added, it is better than basic film heating

25% energy saving and faster than graphene

Fastest to the required temperature using thermal conductivity

The energy saving effect is further improved by

to see.

◈ Enhanced durability

An area of 2630m/2 can be spread per 1g of graphene

A high enough specific surface area is the product's

It plays a role in improving durability.

200 times stronger than steel

Increases durability.

Excellent durability against local heat and moisture

◈ Overheat protection

The problem with film heating is definitely local heat

I can tell you that if you keep the heat for a long time, you can get local heat

This will cause damage to the film.

PTC + Graphene These are only mutually beneficial

Maximize the energy saving effect and overheat prevention

It will be solved at the same time.

PTC graphene film heating has very good durability

It shows the electrical heating properties of the original state again.

◈ Eco-friendly products

Due to the toxicity of chemicals during product production

Due to the dust collection facilities should be good and the worker

It must have had an adverse effect on health.

It's feed.

PTC graphene film heating is conventional CA, BGA

Produced using PMA without using

The product can be said to be an eco-friendly product

Graphene forced overheating test

| General film heating | PTC film heating | Graphene PTC | ||||

|---|---|---|---|---|---|---|

| Time | Temperature | W | Temperature | W | Temperature | W |

| 00:00 | 21℃ | 129W | 21℃ | 126W | 21℃ | 126W |

| 10 minutes elapsed | 64℃ | 125W | 61℃ | 105W | 56℃ | 107W |

| 20 minutes elapsed | 69℃ | 123W | 61℃ | 105w | 58℃ | 106w |

| 30 minutes elapsed | 74℃ | 122W | 64℃ | 105W | 61℃ | 105W |

| 40 minutes passed | 78℃ | 121W | 72℃ | 104W | 65℃ | 105W |

| 50 minutes passed | 82℃ | 120W | 74℃ | 103W | 68℃ | 104W |

| 60 minutes elapsed | 90℃ | 121W | 79℃ | 103W | 69℃ | 102W |

50cm x 5m experiment (temperature measurement when changing wattage)

※Indoor temperature 20℃

| General film heating | PTC film heating | Graphene PTC | ||||

|---|---|---|---|---|---|---|

| Time | Temperature | W | Temperature | W | Temperature | W |

| 15 minutes | 28℃ | 624W | 29℃ | 624W | 29℃ | 624W |

| 25 minutes | 31.9℃ | 624W | 33.3℃ | 570W | 37.6℃ | 569W |

| 35 minutes | 36.9℃ | 623W | 37.2℃ | 566W | 43.1℃ | 564W |

| 45 minutes | 38.9℃ | 623W | 40.1℃ | 560W | 44.4℃ | 554W |

| 55 minutes | 38.9℃ | 620W | 41.7℃ | 560W | 44.2℃ | 557W |

| 1 hour 05 minutes | 40.0℃ | 621W | 42.3℃ | 565W | 45.3℃ | 557W |

| 1 hour 15 minutes | 40.3℃ | 621W | 42.5℃ | 561W | 45.6℃ | 557W |

| 1 hour 25 minutes | 41.4℃ | 625W | 42℃ | 564W | 45.8℃ | 557W |

| 2 hours 15 minutes | 42℃ | 621W | 42.5℃ | 567W | 46.7℃ | 557W |

| 3 hours 15 minutes | 43.2℃ | 623W | 42.3℃ | 564W | 47.5℃ | 557W |

| 4 hours 15 minutes | 43.5℃ | 655W | 43.0℃ | 563W | 47.6℃ | 557W |